- Crystallizer Series

- MVR Evaporators

- Complete System Engineering

- Scraper type film evaporator

- Distillation tower equipment

- Energy-Saving Sewage

- Waste Water Sewage

- Energy-Saving Waste Water

- Reaction & stirring equipment

- Heat-Exchange Condensing

- Drying and Dispersing Equipmen

- Tank Series

- Fermentation Equipment

- Concentration Evaporation Faci

- Extraction, Filtration, Precip

|

|

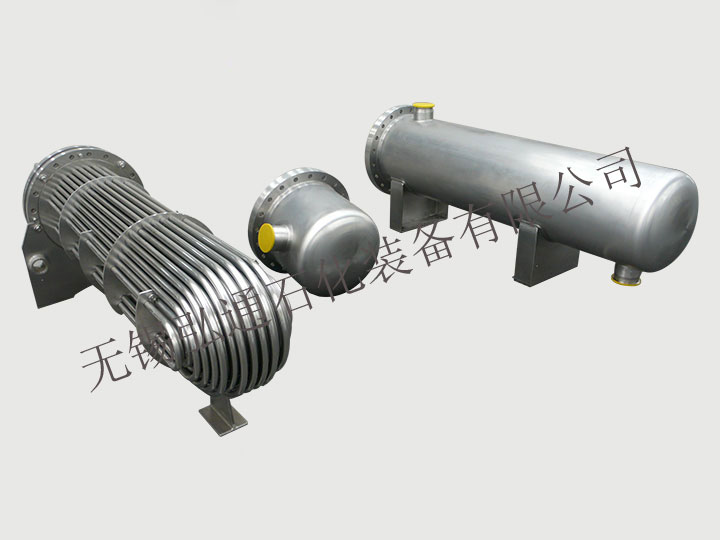

产品概述/Product overview

钛材换热器是由一系列具有一定波纹形状的金属片叠装而成的一种新式换热器各种板片之间形成薄长方形通道,经由过程半片进行热能互换它与通例的管壳式换热器相比,在相同的流动阻力和泵功率消耗情况下,其传热系数要高出多,在适用的规模内有代替管壳式换热器的趋势。钛板式换热器、热互换器行业板片常用的材料主要有奥氏体不锈钢、钛及钛合金、镍及镍合金等冷轧薄板工业纯钛127用于板式换热器,工业纯钛276和Ti-0.3Mo-0.8Ni345用于管式换热器用TA1钛板打造的板式换热器,相比列管式换热器有多长处,在市场上有强的竞争力,主要用于化工、石油、舰船、海水淡化等热互换系统。

Titanium heat exchanger is a series of a certain corrugated shape of the metal sheetstacked from a new type of high efficiency heat exchanger between the various plates to form a thin rectangular channel, through the half of the heat exchange with it.Compared with the case of the same flow resistance and pump power consumption, the heat transfer coefficient is much higher than that of the shell-and-tube heat exchanger, and there is a tendency to replace the shell and tube heat exchangerwithin the applicable scale. Titanium plate heat exchangers, heat exchangers Industry board commonly used materials are mainly austenitic stainless steel,titanium and titanium alloy, nickel and nickel alloy cold-rolled sheet industrial pure titanium 127 for plate heat exchanger, industrial titanium 276 and Ti-0.3Mo-0.8Ni345 for tubular heat exchanger with TA1 titanium plate to build the plate heat exchanger, compared with the tube-type heat exchanger has many advantages in the market has a strong competitive edge, mainly with In the chemical, oil, ship,desalination and other hot swap system.