- Crystallizer Series

- MVR Evaporators

- Complete System Engineering

- Scraper type film evaporator

- Distillation tower equipment

- Energy-Saving Sewage

- Waste Water Sewage

- Energy-Saving Waste Water

- Reaction & stirring equipment

- Heat-Exchange Condensing

- Drying and Dispersing Equipmen

- Tank Series

- Fermentation Equipment

- Concentration Evaporation Faci

- Extraction, Filtration, Precip

|

产品主要用途/Main purposes of the product 反应锅由锅体、锅盖、搅伴器、电加热油夹管、支承及传动装置、轴封装置、溢油槽等组成,并配有电加热棒及测温、测压表。 由于用户因生产工艺、操作条件不尽相同,搅拌形成一般有锚式、浆式、涡轮式、推进式或框式。支承座有悬挂或支承式二种。 夹套内放置导热油,由电热棒加热,夹套上开有进、排油、溢测量、放空及电热棒、测温等接管孔。夹套外壁焊接支座,锅体下部开有放料口。 |

|

The reaction vessel is composed by main body, cover, stirrer, electric heating oil clip pipe, supporting and driving device, shaft sealing device and oil overflow tank, etc. It is also equipped with electric heating bar and temperature, pressure measuring gauge. The stirring form includes anchoring type, pulp type, turbo-type, push type or frame type according to different production processes and operation conditions. The supporting seat has two types: suspended type or supporting type. Heat conduction oil is filled inside the jacket and heated by the electric heating bar. There are openings on the jacket for pipe connecting for oil inlet, oil outlet, overflow measuring, venting& electric heating bar and temperature measuring. The external wall of the jacket is welded with support and there’s material discharging port at lower part of the vessel body. |

|

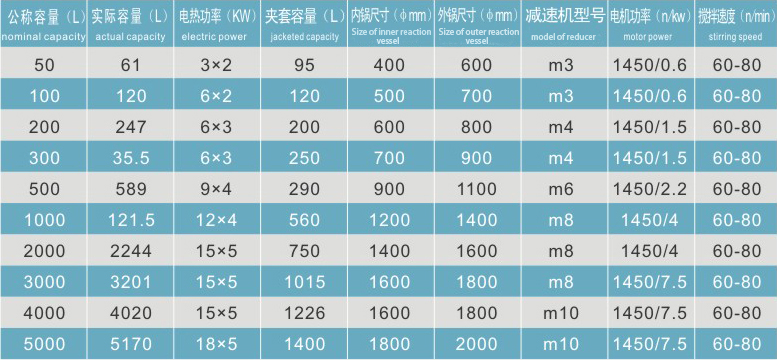

| 主要技术参数参考表/Reference table of main technical parameter |